Sigma

Sigma Sigma

Sigma

This situation took place in November 1984. I was the EIC for a 53‐foot TV production trailer. This was for E.J. Stewart, a Philadelphia‐based company. This "situation" I've seen three times, but this one was the first, and we didn't know what we were in for. The other two I knew about a head of time.

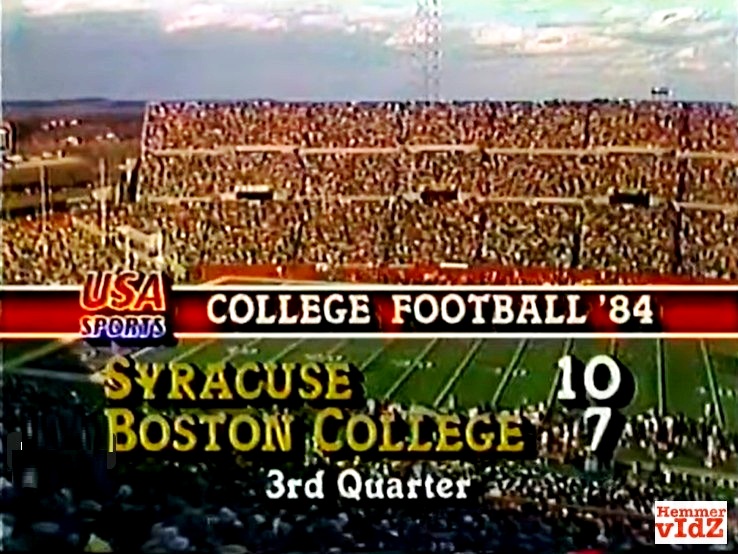

That Saturday, the 17th, was a crisp, cool day at Sullivan Stadium. This venue, once called Schaefer Stadium, is located in Foxborough, Massachusetts. It was a college game with Syracuse pitted against Boston College. We thought we were there to provide coverage for a football game. While we were there to help with that, our mission, unbeknownst to us when we showed up, was something we hadn't knowingly signed up for.

Our client, an early fledgling cable network, USA, expected us that day to take the game coverage from another production trailer as a feed at game time and to act as the entire USA network starting at 7 a.m. and continuing for the next 12 hours. Oh yeah, besides running "Leave It to Beaver" and "Bonanza" episodes, we ran all their commercial breaks and other ancillary programming.

But our contibution didn't end there, we were expected to separately provide pre, half, and post‐game coverage with equipment from our truck. That was the entire scope as it was explained to me at the beginning. Now setup and operation of a television production trailer is far different than the operation of a master control facility.

Now for those of you not familiar, Master Control is the main hub of a TV station, network, or cable operation. It handles all video, audio, and data signals. It manages, monitors, and distributes both incoming and outgoing signals. It ensures that programming, commercials, and live broadcasts air correctly and on schedule.

We were expecting that we would be a "sidecar truck" or "B unit." The main truck (A unit) handles the primary broadcast. The sidecar (B unit) takes a feed from the main truck. It adds its own cameras, graphics, or commentary. Then, it produces a separate broadcast for another network or rights holder.

This is often used in events that need special coverage. Examples include international sports, political debates, and award shows. The sidecar truck may have its own director, producer, and replay operators. However, it relies on the main truck for most core production elements.

We should have asked more questions during the early planning phone calls. The fact that we were showing up at 6:30 a.m. for a 1:00 p.m. game should have raised some flags. But I believe at the time we chalked it up to the fact that USA was still a young fledgling looking to cut costs. BTW: these one day set, shoot, and strike productions are known as S3s.

When we showed up at 6:30 a.m. three or four production assistants, a associate producer and associate director where waiting. They wanted into the trailer and start loading up tapes immediately.

Whoa! The normal routine when a truck shows up is to unstow many parts of the trailer. While expando‐type trailers became the rage, my truck was still what we called a "straight" truck. I know the terminology doesn't translate well to today. That simply meant it didn't have an expansion section to crank out. That aside, there were still chairs and other items that had to be stowed for travel.

But two big things that consumed the most time after parking were powering the trailer. Production trailers consume a lot of power, even back then. While at that time it was not unusual to need 100KW of power. That was a fairly common amount back then. In the 90s, production trailers went digital. Their power needs often more than doubled. With the HD rollout a decade later, it experienced a significant increase once more.

With the normal 100KW of power of the day, you don't just find a plug and plug in. No, the current draw is such that you often need four separate cables. Each was half an inch in diameter or thicker. These cables had to be temporarily clamped to the power buses in the breaker box. These clamps had knobs that would be turned to clamp onto the buses. I knew them as "clip clamps." Sometimes, you had to clamp onto the power buses even when the circuits were still live. Hopefully using heavy insulated rubber gloves and the "one hand rule" for electrical safety. Look it up.

Anyway, to play it safe, it was never a good idea to rush through connecting to power. No matter how many producers are behind you tapping their feet. The other big thing is getting the stairs out and hooking them to the trailer. This truck had four. They were heavy and large enough that it took two people.

We didn't quite make their 7:00 a.m. on‐air target. It was the start of a bad day.

In normal remote production, the crew sets up their positions first. Then, they help in other areas once they have control of their stations. While there was not much in the way of computer control setup back then, there was a fair bit of manual setup.

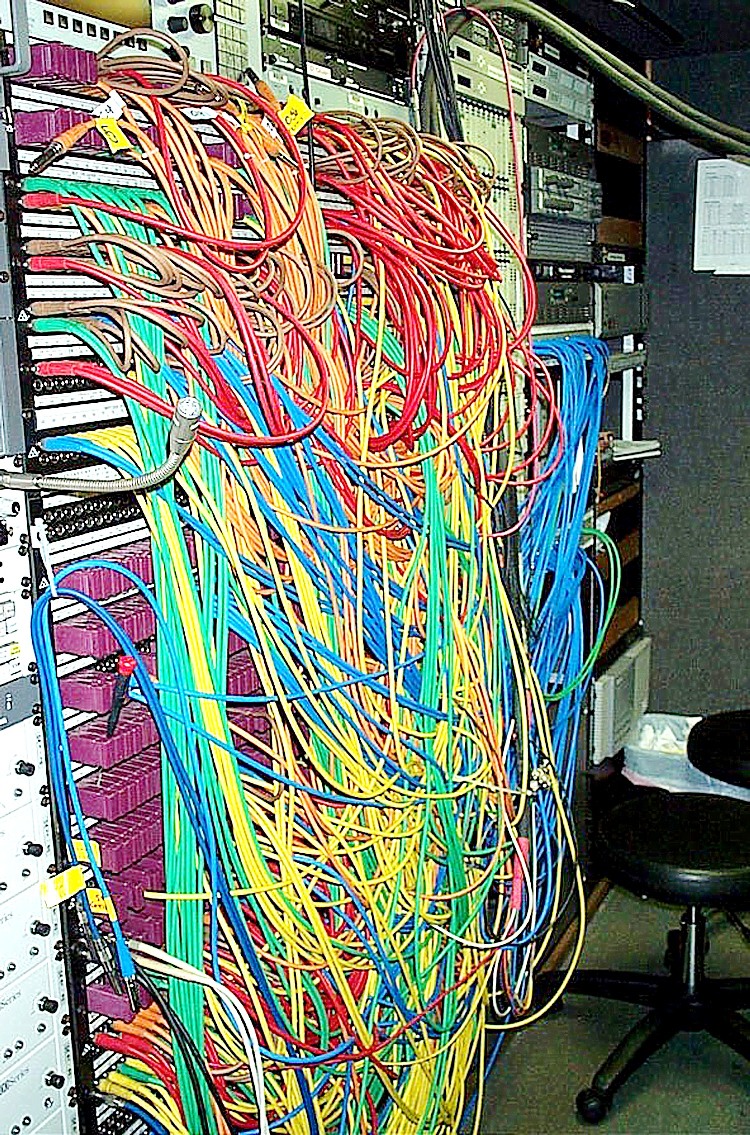

While there were video and audio routers back then, they were expensive, and my truck didn't have one. We routed the old‐fashioned way. By patching. Both video and audio. Each production is different, and still generally is to this day. What the trailer had was a lot of video and audio distribution amplifiers (DAs for short). The producer or director would fill out a chart of where they wanted the sources to show up on the "monitor" wall. We would connect sources to recorders and other destinations by patching them into DAs. On my truck, we patched DA outputs to whatever needed to see a specific source.

Often the EIC (me in this case) would handle the video patching while the A1, the main audio mixer would handle the audio patching. The technical director, or TD, operates the video switcher. They must load any preset effects into the switcher. These effects were crude by today's standards. By the turn of the century, routers had become ubiquitous. You could quickly recall and change previous setups using computer apps for all these areas.

The A1 mixes the audio and is generally in charge of the audio and intercom efforts

The problem we were facing was that this was a production that was being set up, or provisioned to use a Telco term, not based on the pre/half/post shows we were responsible for during the actual game. Instead, we would patch and configure based on the next VTR or source that the USA needed to send to the satellite. Instead of 5 hours of setup for the main event, we spent a couple of hours getting the trailers' "food chain" to a point where we could act like the USA Network, a crude version of it anyway, before turning to get ready for the "main event."

Now skip this section if you think it getting too far into the weeds. I also faced a technical issue I had never seen before. Back then, analog video sources had to sync with each other. How close timing wise? You'd see color changes when mixing two different sources if their signals were off by a few nanoseconds. To accomplish that, all video signals had to be locked to a common reference. A process called "genlocking." In this case, my truck needed to sync with the main game trailer. So, we used the other trailer's reference generator to genlock. Even though we were considered the "network."

That day, I gained new technical knowledge, not to discount all the logistical nuggets thrown at us that day. What we "genlocked" to was that trailer's final output feet, I thought. What I didn't know is that for some reason it was not the trailer's final output. It was one step in the food chain from the final output.

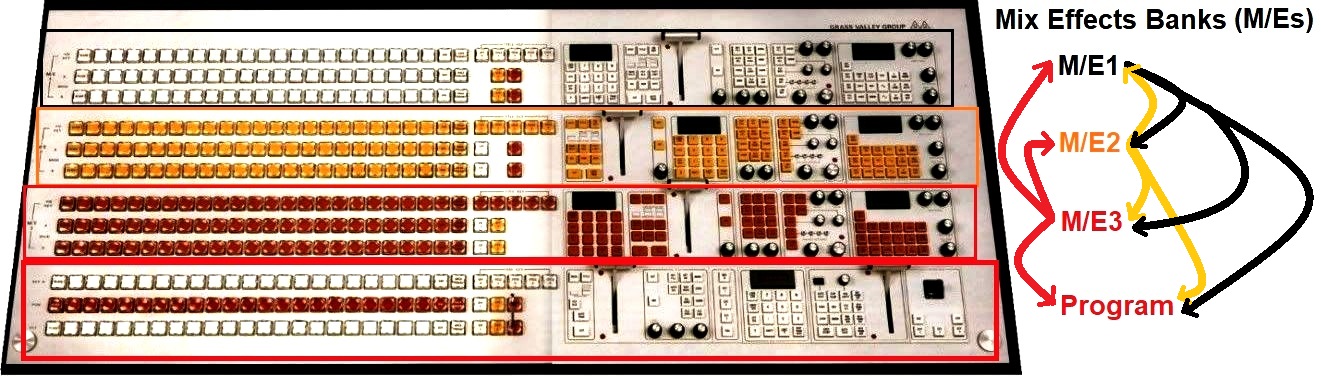

In the past, video switchers were made up of several sub switchers in one box. They shared a common control panel. Each sub switcher, known as a Mix/Effects (M/E) bank, could work alone. They can also be cascaded. This means one switcher feeds into the next M/E, which then feeds another, and so on. High‐end switchers usually had four of the M/E banks. One might have a composite video image, say a split screen of two people talking. That output would cascade to the next where a key with their names could be added. That could cascade to another where a scorebox graphic could be added, etc.

Before that switcher, the order of M/E banks in creating the final video was set. Generally, M/E 1 fed M/E 2, which fed M/E 3, which finally hit the 4th. The 4th was not referred to as an M/E bank, but the "Program" bank, as it produced the final "program" output. That is how they worked until this switcher in the other trailer was introduced in time for the 1980 Summer Olympics.

![]()

ABC still held the Olympic rights in 1980. They wanted a new video switcher with a different design. At the time, ABC had a close relationship with a company called Grass Valley. RCA owned NBC at the time, and thus NBC had a giant research lab. CBS had CBS Labs, which was smaller than RCA but well‐respected. Although at this time a decade had passed since CBS sold it to Thomson‐CSF. ABC had chosen Grass Valley as their research and development lab.

What ABC wanted, and got, was a switcher that wasn't fixed in the order that video cascaded through it. Not M/E 1 to 2 to 3 to program, but the M/Es could be in any order: 3 to 1 to 2, as an example. So what was the big deal from my perspective?

A universal constraint is everything takes time, even if it is only a few milliseconds. As video passed from one M/E bank to the next, it was delayed a few milliseconds. So, as the video cascaded from one bank to the next, it got delayed a bit. Now, each bank all had the same sources so that camera 3 appeared on every bank. To include camera three in an effect on M/E 2, you need to delay it. This ensures it matches the video from M/E 1. They would have to delay camera 3 and all the other inputs even more in feeding M/E 3.

Talk about convolution!

The old way that I was used to meant that I could predict the timing of the output of each bank. With this new switcher, that was no longer the case. The timing of a bank, say M/E 2 depended on where it was in the switcher's cascading M/E bank food chain. Again, I was unaware of that.

So what we thought was a hard reference, coming from one of the other trailers M/E banks. But in reality, it could be jumping around in time, depending on what order the TD had these banks in. No problem if they are not changing that order. But that TD had effects where they would re‐order the banks. What happened every time he did that? All the sources on my truck, the sources that were going out as the USA Network, would take a major hit. Every video monitor on the trailer would glitch. Extremely disconcerting. It was clear that the USA folks were unhappy. I looked at the reference on a waveform monitor and I could see it change in time when the upset happened each time.

I was finally able to get my counterpart on the game truck to look at what we were seeing. He knew how his newer switcher worked. He grasped the situation immediately. He gave us a different, stable video signal as a reference. Problem solved. But by this point, the USA folks were completely on edge. This horrible day wasn't over yet.

BTW: Within a few years, this timing problem wouldn't have mattered. As digital video technology improved and computer memory got cheaper and faster, a new must‐have device came onto the market. The frame synchronizer, or simply frame sync, became both affordable and common. It takes a video signal that isn't synced with your equipment. It stores that signal in memory and sends it out in sync with your signals. Back in the analog days, the video was converted to digital and converted back to analog on its way out.

During the 90s, digital video adoption accelerated. Digital audio also gained some traction, but not as much.

Now, as kick‐off approached, an interesting but not fun dance emerged. Most of the operators were concerned with playing network, and not so much with the pre‐game coming up, which, if you remember, was in our purview. While most were OK juggling both, it was the USA Networks and producers who had the most trouble converting from network mode to game mode.

Part of the problem that everyone faced was that in a facility geared towards master control and program release, as it was sometimes called, even in the 80s things were highly automated and it was mostly run by automation apps from companies that specialize in that. My truck had none of that. It was geared for live, or live‐to‐tape productions. Most master controls at that point in time had what a layperson would call a video jukebox. This was a decade before the first video servers arrive on scene. It would be a system with two or more VTRs, along with a robotic tape handling system that would retrieve tapes for storage bins and load them into a machine. No human handling.

While USA showed up with a combination of spot reels and individual tapes. A spot reel is where all the commercials are recorded on a single reel of tape. Good and bad. Good if nothing needs to be added or dropped from playback. A logistical challenge if they need to skip something on the reel or have to change the order of playback. Which did happen a half‐dozen times or more. That made for extra work for the tape operators that ended up having to dub (fancy word for copy) the changes to another machine.

It was almost a reprieve when the kick‐off finally came. Even with half‐time and post‐game shows ahead, the game's routine calmed most people. That is until lightning struck. Actually, it was a golf cart. During the third quarter, the whole trailer lurched about 4‐6 inches. As was often the case as an EIC, you often weren't, at least back then, doing much. This was well before cell phones and email. As was sometimes the case, I would find a nook in the truck to sit in, and if there wasn't a chair, I'd often sit on the floor. Then came something that I had never experienced before. Trailer movement in the middle of an event.

Our sense of rhythm came to an abrupt halt. I didn't need to listen to the intercom to know that the people up in the production compartment were not happy.

Scrambling out and down the stairs and knowing the direction the trailer moved headed to the trailer's rear. There we found a young man dazed, his arm bleeding. Security showed up and the "crash dummy" had no explanation of how he did what he did. He had enough momentum that he put a discernible crease in the trailer's bumper. One of the few lucky breaks that day was that the trailer's landing gear didn't collapse or come off the wood that was under them. Sometimes, to level the trailer you will find the landing gear on a stack of wood. That could have been catastrophic if that day had been so.

Finally, the game was over, along with the post‐time show. The main game truck could completely strike. My truck could strike cameras and other things in the stadium itself. But network operations continued inside the trailer for another three hours. I was deathly afraid that in tearing down the other trailer, something we still needed would be disconnected. Our second piece of luck for the day: that didn't happen.

During teardown, I finally found out why my truck did the pre/half/post shows. The other trailer needed to hit the road without delay. Since it defaulted to us for the post‐game setup, they decided we would handle the other two segments.

But by this point, the crew in the trailer was very tired and a bit testy, as were the USA folks. When network operation finally came to an end and was handed back to HBO, I believe, there were not any pleasantries between the client and me. USA simply collected their tapes and left. That left the driver and me to stow what was left undone, disconnect the power, and stow the stairs. We were out of there finally just before 8 p.m.